Last Updated on: 17th May 2024, 09:37 am

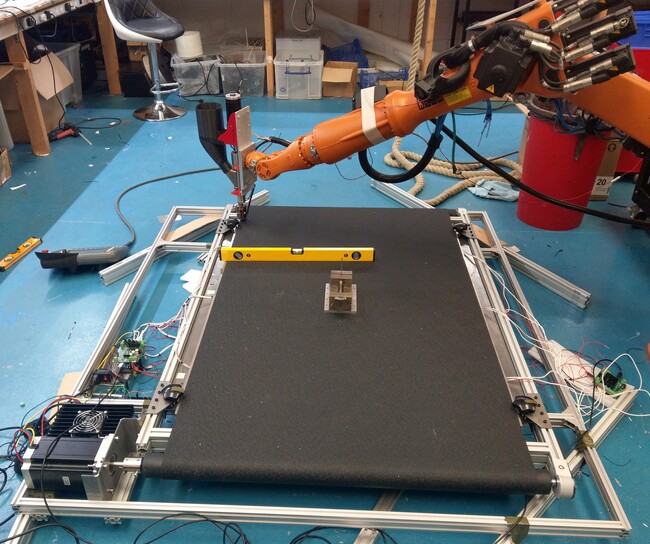

Noztek‘s revolutionary roller conveyor, which is fully programmable, is poised to transform the world of robotic 3D printing. This cutting-edge system features a heated bed that plays a crucial role in an autonomous printing setup, enabling the efficient production of numerous parts with minimal human intervention. According to Steven Forster, the founder of Noztek Innovations, this system has the potential to operate non-stop, 24/7, and can produce thousands of products using a wide range of advanced materials, including carbon fibre composites and other exotic thermoplastic combinations.

The heated bed of this innovative conveyor allows users to print multiple parts simultaneously, effectively utilising the entire print bed. Once the printing process is complete, the roller is programmed to spin half a revolution, expertly dislodging the printed parts and preparing the bed for the next print run. This seamless automation ensures a continuous and efficient workflow, eliminating the need for constant manual intervention.

Engineered with precision, the bed of this roller conveyor is constructed using an aluminium subframe, incorporating a sturdy 5mm steel support bed. The top base plate is equipped with six 750w independently mounted heater panels, ensuring optimal and consistent heating throughout the printing process. The roller itself is powered by a high-torque stepper motor, connected to Noztek’s bespoke PCB and an Arduino Mega. The code facilitates seamless communication with the Kuka controller, which has been preprogrammed to synchronise the movement of the bed roller with the completion of each print run, ensuring precise and efficient operation.

In addition to its remarkable capabilities, this roller conveyor can also function as an infinity print bed, enabling the production of extra-long 3D prints. By utilising the robotic arm to print at a 45-degree angle, the conveyor belt incrementally moves by 1 degree after each layer is produced. This ingenious mechanism allows for the creation of extremely long parts, limited only by the available workspace. By adding connecting supports to one end of the conveyor, users can effortlessly print elongated objects with unparalleled ease and precision.

The dimensions of this state-of-the-art roller conveyor are impressive, measuring 1.5 metres in length and 1 metre in width. Despite its robust construction and advanced features, it weighs a mere 60 kilograms, making it highly portable and adaptable to various manufacturing environments.